Mixer Division

Clients We

Work with

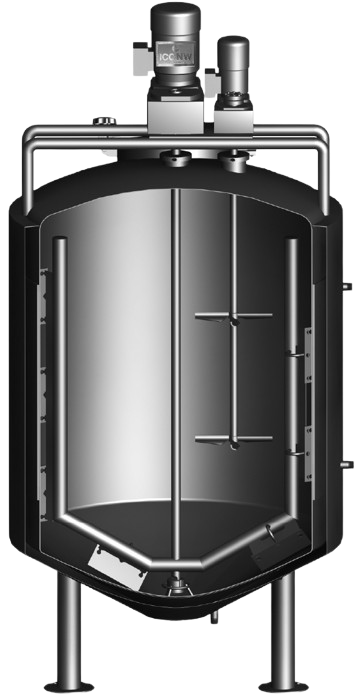

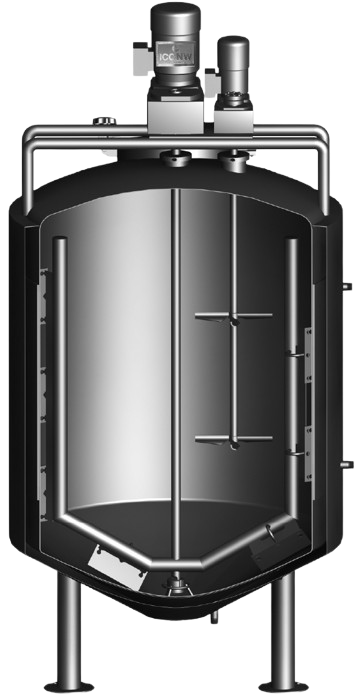

A Perfect Blend of Mixers and Tanks

ICC Northwest constructs mixers in-house for vessels and tanks to aid in heat transfer, mix ingredients or adjust the product using gas dispersion or emulsification.

The ICC NW Mix Tank: Where all components are perfectly matched for efficiency and performance. Cleaning devices reach every corner and do not interfere with shafts and impellers. Instrumentation is properly located to avoid false readings. Heat transfer jacketing is sized for batch loads or zoned for flexibility.

The whole process from shaft sizing to seal design is more effective when it comes from one source, and that source is ICC NW. We combine tank fabrication expertise with our Mixer Engineering Department to offer a wide range of experience in agitation technology.

Tank Technology + Mixer Technology = The Ultimate Mix Tank

- Faster start-ups

- Mixer-to-tank testing

- Pre delivery assembly

- No mismatches

- Quicker delivery

- Lower start-up costs

The following mixer designs are ICC NW’s standard models. Custom designs are also available to meet your specific needs. If a higher viscosity product is required than listed in the process parameters, please consult the factory.

Engineering Analysis

Sanitary Design Experience: ICC NW engineers are well acquainted with 3A, ASME standards, and all applicable codes. The requirement to pass spray-ball coverage tests for mix vessels gives ICC engineers a unique insight into CIP performance on mixers.

Rheology Lab

The Mixer Test Lab uses the principle of rotational viscosity measurement. A spindle is immersed in the fluid sample and the torque resistance is measured at a constant speed.

The programmable viscometer will accurately (+ or – 1%) measure fluids with viscosities from 15 6,000,000 cps (centipoise). On-site analysis is a service offered by ICC NW. NIST traceable viscosity standards, data capture and retention capability (including temperature) are also provided.

Our Mixer Lab will

- Define the fluid characteristics of your product

- Assist in the development of new products

- Quantify and measure ICC NW mixer performance

- Perform on-going scientific research and development

The rheology of the fluid is important, as well as the desired mixing levels, utilities available, time constraints, and any unusual consideration such as, explosive atmospheres, foaming or other unique mixing characteristics.

Viscosity Guide

| Fluid | Viscosity (cent) |

|---|---|

| Water | 1 |

| Blood | 70 |

| Cough Syrup | 190 |

| Sugar Solution 68 Bric @ 60 F | 360 |

| Honey | 1,500 |

Gasket Materials Guide

| Property Resistance | Buna-N | EPDM | Silicone | Fluoro-elastomer (Viton R) | fluoro-polymer (Teflon ®) |

|---|---|---|---|---|---|

| Ozone | Fair | Excellent | Excellent | Excellent | Excellent |

| Vapor & Heat | Fair | Excellent | Excellent | Excellent | Excellent |

| Heat | Good | Good | Excellent | Excellent | Excellent |

| Cold | Fair-Good | Good | Excellent | Good | Excellent |

| Abrasion | Good | Good-Excellent | Fair-Good | Good | Fair-Good |

| Acid | Good | Good-Excellent | Good | Good | Excellent |

Vintage Standard

ICC Northwest’s Standard Sanifoil Mixer. This design is very easy to CIP wash. The mixer provides robust radial and axial flow. Efficient blending of miscible liquids and easily dissolved solids, producing batch uniformity and aiding in heat transfer.

Typical Products:

- Maple Syrup

- Motor Oil

- Water-like Liquids

Vintage Light Duty

ICC NW’s Light-duty Sanifoil Mixer. This design is very easy to CIP wash. The mixer provides robust radial and axial flow.

Use for light duty blending and mixing of low viscosity products, producing homogenous mixtures and solutions.

Typical Products:

- Anti-Freeze

- Blood

- Water-like Liquids

Vintage Heavy Duty

ICC NW’s Heavy-duty Sanifoil Mixer is built with larger, slower moving impellers. The mixer provides robust radial and axial flow.

Use for the effective mixing and dispersion of light solids and moderately viscous liquids, producing batch uniformity and promoting heat transfer.

Typical Products:

- Honey

- Motor Oil

- Water-like Liquids

Vintage Horizontal

ICC NW’s Horizontal Mixers provide gentle blending and maintain uniformity in large vessels. Two-speed motors will prevent foaming and splashing when mixer is operated at or near product level. This mixer is readily disassembled, without tools, for inspection of seal components.

Use for the gentle blending of low viscosity products, producing and maintain batch uniformity and facilitate heat transfer.

Wide variety of impellers available.

Typical Products:

- Light Syrups

- Light Oils

- Water-like Liquids

Bottom Sweep

ICC NW Sweep n’ Stir Mixers feature the same rugged heavy duty bearings, lower sanitary steady bearing, and gear reducer protection included with the Vintage series. On-center mounting with sanitary removable and adjustable angle baffle. The close clearance lower blade provides low level, gentle sweeping action and is easily cleaned. Additional upper blades are available for tall tanks.

Use for the thorough mixing of higher viscosity products without producing excessive foam, maintaining mix quality and aiding in heat transfer.

Typical Products:

- Light Syrups

- Molasses

- Heavy Creams

Full Sweep

ICC NW Sweep n’ Stir Mixers feature the same rugged heavy duty bearings, lower sanitary steady bearing, and gear reducer protection included with the Vintage series. On-center mounting with sanitary removable and adjustable angle baffle. This mixer will handle higher viscosity products that flow impeller style mixers cannot efficiently address.

Use for the gentle mixing of high viscosity miscible liquids and dispersion of large solids, maintaining batch uniformity and promoting heat transfer.

Typical Products:

- Chocolate Syrup

- Ketchup

- Heavy Juices

Full Scrape

ICC NW Scrape n’ Fold Mixers feature the same rugged heavy duty bearings, lower sanitary steady bearing, and gear reducer protection included with the Vintage series. On-center mounting with sanitary removable and adjustable angle baffle. This mixer gently scrapes the bottom and sidewalls of the vessel to prevent product burn-on and for good mixing performance on the highest viscosity products. Conical or hemispherical bottoms are preferred to ensure good performance.

Use for the thorough mixing of higher viscosity products without producing excessive foam, maintaining mix quality and aiding in heat transfer.

Typical Products:

- Light Syrups

- Molasses

- Heavy Creams

Offset Mount Dual Motion Mixer

- Fluid mixing up 100,000cps (consult factory for higher viscosities)

- Use for two component mixing of highly viscous liquids

- Gentle blending / folding action to maintain particulate integrity

- High viscosity blending with near complete blade coverage

- Typical operating speed: Scraper: 12-30 RPM; Turbine: 50-90 RPM; High shear: 1750 RPM

Typical Products:

- Cosmetics

- Heavy Concentrates

- Purees

Super Duty:

- Fluid mixing up 150,000cps (consult factory for higher viscosities)

- Gentle blending / folding action to maintain particulate integrity

- High viscosity blending with near complete blade coverage

- Typical operating speed: Scraper: 12-30 RPM; Turbine: 50-90 RPM; High shear: 1750 RPM

- Able to add a third top mixer or hanging baffle

Typical Products:

- Cosmetics

- Tomato Paste

- Mayonnaise

Double Duty:

- Fluid mixing up 75,000cps (consult factory for higher viscosities)

- Use for two component mixing of highly viscous liquids

- Gentle blending / folding action to maintain particulate integrity

- High viscosity blending with near complete blade coverage

- Typical operating speed: Scraper: 12-30 RPM; Turbine: 50-90 RPM; High shear: 1750 RPM

- Able to add a third top mixer or hanging baffle

Typical Products:

- Cosmetics

- Juice Concentrates

- Soups

Concentric Mount Dual Motion Mixer

ICC NW Concentric Mount Mixer is used in applications where more than one mixing action is required, and for processors who require the flexibility to address a wider variety of products. The most common configuration is a scraper/turbine combination. Other configurations include a center sweep style mixer and substituting a high shear style mixer for the turbine.

This style of mixer is constructed where both mixers are concentrically mounted and rotate in opposite directions. Two sanitary steady bearings are used to support each shaft eliminating the bending moment caused by concentric mounting. A rigid cross arm stiffens the scraper frame to handle the most severe service. The most common configuration is a scraper/turbine combination. For additional product movement in high viscosity applications, multiple flow impellers are combined to ensure complete product movement with no dead zones.

Double Duty:

- Fluid mixing up 100,000cps (consult factory for higher viscosities)

- Use for two component mixing of highly viscous liquids

- Gentle blending / folding action to maintain particulate integrity

- High viscosity blending with near complete blade coverage

- Typical operating speed: Scraper: 12-30 RPM; Turbine: 50-90 RPM; High shear: 1750 RPM

Typical Products:

- Cosmetics

- Heavy Concentrates

- Purees

Super Duty:

- Fluid mixing up 500,000cps (consult factory for higher viscosities)

- Gentle blending / folding action to maintain particulate integrity

- High viscosity blending with near complete blade coverage

- Typical operating speed: Scraper: 12-30 RPM; Turbine: 50-90 RPM; High shear: 1750 RPM

- Able to add a third top mixer or hanging baffle

Typical Products:

- Cosmetics

- Peanut Butter

- Fats

Offset Mount Triple Motion Mixer

ICC NW’s Triple Duty Mixer is used in applications where high shear mixing is required in addition to dual motion. These mixers are the most versatile available and provides a universal mix tank that can handle nearly any product.

Used in applications where high shear mixing is required in addition to dual motion. These mixers are the most versatile available and provides a universal mix tank that can handle nearly any product. The most common configuration is a center mounted scraper with an offset turbine style mixer and an offset top entry high shear mixer.

Triple Duty:

- Fluid mixing up 150,000cps (consult factory for higher viscosities)

- High shear mixer for adding difficult to incorporate ingredients

- High viscosity blending with near complete blade coverage and high shear capability

- Typical operating speed: Scraper: 12-30 RPM; Turbine: 50-90 RPM; High shear: 1750 RPM

Typical Products:

- Shortening

- Cosmetics

- Pastes

Concentric Mount Triple Motion Mixer

ICC NW’s Triple Duty Mixers provide high speed, high shear vigorous mixing action for dissolving difficult to wet powders and gums that require a shearing action to break up clumps. Available in both top entry and bottom entry configurations. Housed in a stainless steel mount with oversized bearings for long life. Bottom entry style mixers feature a double mechanical seal for long life and are available in a belt drive configuration to eliminate the possibility of water entry into the motor.

These mixers are designed to solve the most challenging of mixing problems. Used in applications where high shear mixing is required in addition to dual motion. These mixers are the most versatile available and provides a universal mix tank that can handle nearly any product. The most common configuration is a center mounted scraper with an offset turbine style mixer and an offset top entry high shear mixer.

Triple Duty:

- Fluid mixing up 250,000cps (consult factory for higher viscosities)

- Blending of difficult to wet powders and liquids

- Break up clumping powders

- Typical operating speed: 1750, 3545 RPM

Typical Products:

- Smoothies

- Dispersions

- Purees

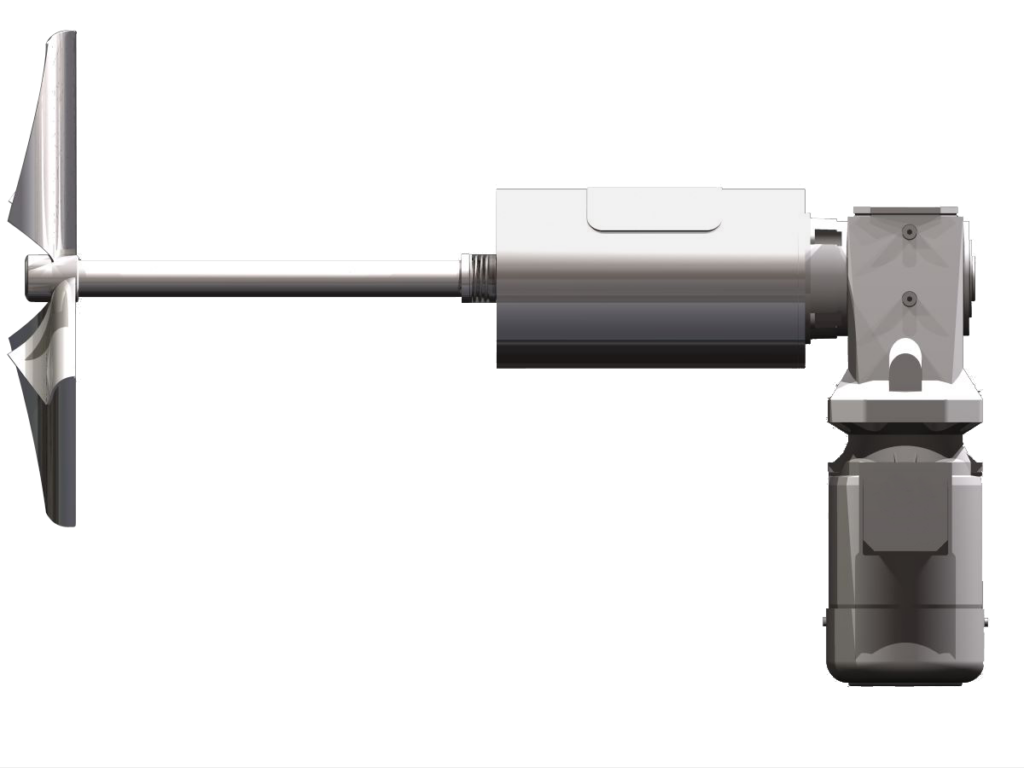

Bottom entry, high shear

ICC Northwest’s Shear Vigor Mixers provide high speed, high shear vigorous mixing action for dissolving difficult-to-wet powders and gums that require a shearing action to break up clumps. Housed in a stainless steel mount with oversized bearings for long life. Bottom entry style mixers feature a double mechanical seal and are available in a belt drive configuration.

Application:

- Fluid mixing up 15,000 cps (consult factory for higher viscosities)

- Blending difficult-to-wet powders and liquids

- Break up clumping powders

- Typical operating speed: 1750, 3545 RPM

Typical Products:

- Purees

- Dispersions

- Smoothies

Top entry, high shear

ICC NW Shear Vigor Mixers provide high speed, high shear vigorous mixing action to dissolve difficult-to-wet powders and gums that require a shearing action to break up clumps. Housed in a stainless steel mount with oversized bearings for long life.

Application:

- Fluid mixing up 15,000 cps (consult factory for higher viscosities)

- Blending difficult-to-wet powders and liquids

- Break up clumping powders

- Typical operating speed: 1750, 3545 RPM

Typical Products:

- Purees

- Dispersions

- Smoothies

Bottom entry, high shear

ICC Northwest’s Shear Vigor Mixers provide high speed, high shear vigorous mixing action for dissolving difficult-to-wet powders and gums that require a shearing action to break up clumps. Housed in a stainless steel mount with oversized bearings for long life. Bottom entry style mixers feature a double mechanical seal and are available in a belt drive configuration.

Application:

- Fluid mixing up 15,000 cps (consult factory for higher viscosities)

- Blending difficult-to-wet powders and liquids

- Break up clumping powders

- Typical operating speed: 1750, 3545 RPM

Typical Products:

- Purees

- Dispersions

- Smoothies

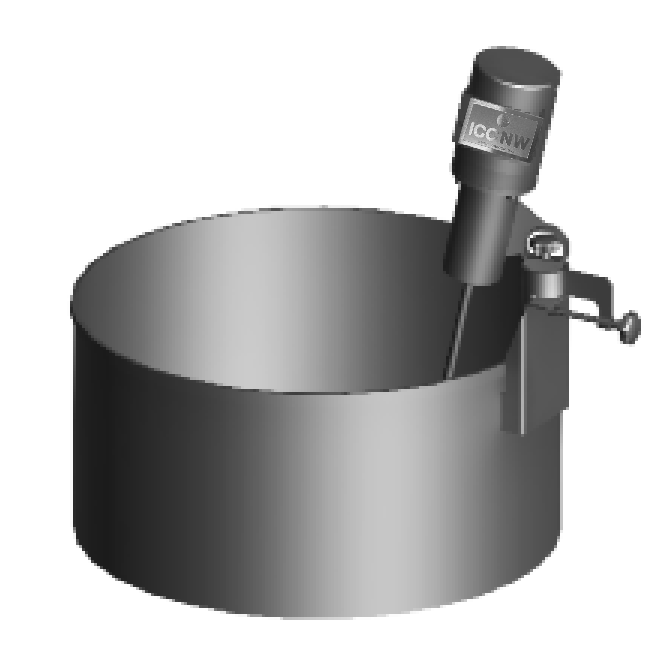

Portable Clamp-on Mixers

ICC Northwest’s Portable Mixers can be clamped in place to the sidewall of an open top vessel or clamped to a mounting bracket welded to the sidewall of the vessel (preferred). The proper mounting angle is 10-15 degree vertical pitch with a 30 degree offset.

Application:

- Fluid mixing up 1,000 cps (consult factory for higher viscosities)

- Blending miscible liquids and easily dissolved solids

- Maintain batch uniformity and aid in heat transfer

- Typical operating speed: 1750 (Direct Drive), 350 RPM (Gear Reduced)

- Air or electric motors optional

Typical Products:

- Light Syrups

- Light Oils

- Water-like Liquids

Pharmaceutical Clamp-on Mixers

ICC NW Pharmablend Mixers are designed with strict adherence to the ASME Bio-Processing Equipment Standard and 3-A Sanitary Standards. Mounted with a sanitary tri-clamp connection for use on Pharmaceutical vessels to meet sterilize-in-place requirements. An oversized mechanical seal is used to provide the specified 1″ annular clearance. Seal area can be readily visually inspected without the need for tools. A debris well (to trap seal fines) with flush port is standard. The flush port is used to assist sterilization by ensuring all seal components reach the required sterilization temperature. Direct drives and gear reduced drives are optional. A stainless steel mount with padlockable access door will prevent unauthorized access to the seal.

Application:

- Fluid mixing up 1,000 cps (consult factory for higher viscosities)

- Blending miscible liquids and easily dissolved solids

- Maintain batch uniformity and aid in heat transfer

- Typical operating speed: 1750 (Direct Drive), 350 RPM (Gear Reduced)

- Low-level, radial-flow (kicker) impeller

Typical Products:

- Sugar Solutions

- Blood

- Water-like Liquids

ICC NW Custom

ICC Northwest offers a wide variety of mixing vessels, including: Sanitary Ribbon Blenders, Scraped Surface Horizontal Blenders, Dual-Motion Scraped/Ribbon Blenders, Complete Skidded Mixing Systems and many others. ICC NW also fabricates a wide variety of special purpose mixers such as mayonnaise emulsifiers, saute fryers, and gate mixers for shortening.

ICC NW Tele-Tilt Mixer

Problem met solution when ICC NW’s creative engineering team crafted the telescoping shaft to accommodate a hinged top, thus requiring minimal clearance. The hinged shaft allows for disassembly of shaft and impellers without pulling drive from vessel. Seal assembly is attached not to mixer shaft, but to the quill shaft, for ease of maintenance and testing.

Brochures

Contact Us For a Quote Today

Custom-made in Canby Oregon to perfectly match for efficiency and performance.