IMPELLERS

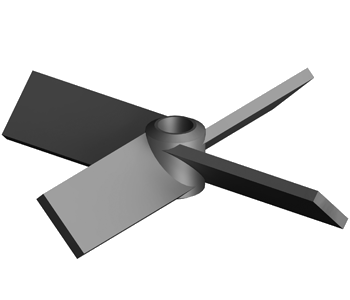

Sanifoil Impeller

Near vertical leading edge captures & redirects CIP spray, washes blade underside. Curved Impeller to Shaft union adds strength, allowing shorter neck which eliminates common CIP shadow. Tapered tailing edge creates axial flow pattern, when channeled, causes uniform velocity along length of blade.

Axial flow + Uniform velocity = Robust agitation

Sloping shoulders of the hub allow cleaning solution to wash hub’s underside. The sloping angle insures complete drainage.

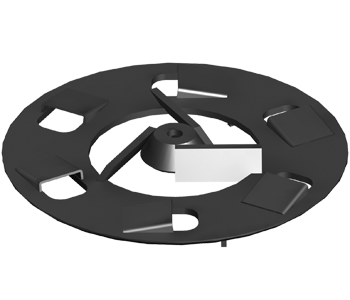

Turbine Impeller

This is an ICC Northwest general purpose impeller. Its versatility allows for a wide variety of mixing applications. Large diameter available.

30, 45, & 90 degree radial

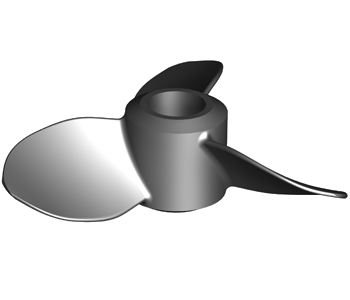

Marine Impeller

This is an ICC Northwest general purpose impeller. Its versatility allows for a wide variety of mixing applications. Size constraints for impeller diameter.

Generally used at faster speeds.

Hydrofoil Impeller

Great balance of flow versus energy use.

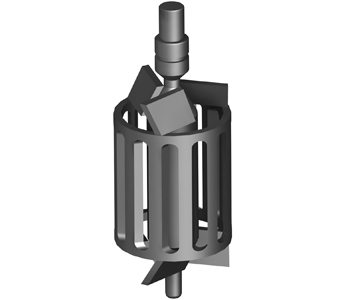

High-Shear Cage

High shear blending for particle size reduction. In-tank homogenizing actions for rapid dispersion.

Higher viscosity applications.

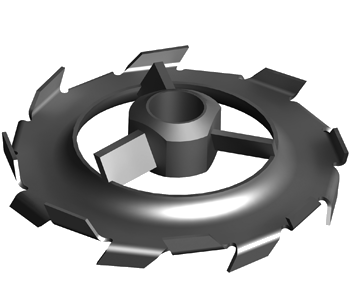

Sani-Shred Impeller

High shear action with excellent flow characteristics. Rapidly disperses product into a uniform mix. Breaks down agglomerate materials in size.

CIP friendly geometry.

Homogenizing Blade

Efficient shearing actions for particle size reduction. In-tank homogenizing, bottom entry. Additional chopping blades available.

Contact Us For a Quote Today

Custom-made in Canby Oregon to perfectly match for efficiency and performance.